Large Power Plants and Small Modular Reactors

Industry-Leading Power Plant Expertise

From complex remote handling systems to cranes built to move high capacity, delicate loads, PAR Systems offers custom designed solutions manufactured and engineered in house by industry-leading engineers. We provide features within our nuclear equipment that are specifically tailored to our customer’s and industry requirements:

- Single failure proof, seismically qualified, radiation-tolerant cranes

- Extremely large, ground-breaking fuel handling systems designed for minimal maintenance and remote operations

- Advanced technology for next-generation SMR and MSR reactors

- Design and field services from trusted experts specializing in power plants and SMRs

Experience Developing Technology for a Wide-Range of Power Plants

Advanced small modular reactors (SMR) are a key part in many country’s goals to deliver safe, clean, and affordable nuclear power options. From molten salt reactors (MSRs) to SMRs, PAR is taking a lead role in working with manufacturers to deliver the specialized technology that can help them expand nuclear operations.

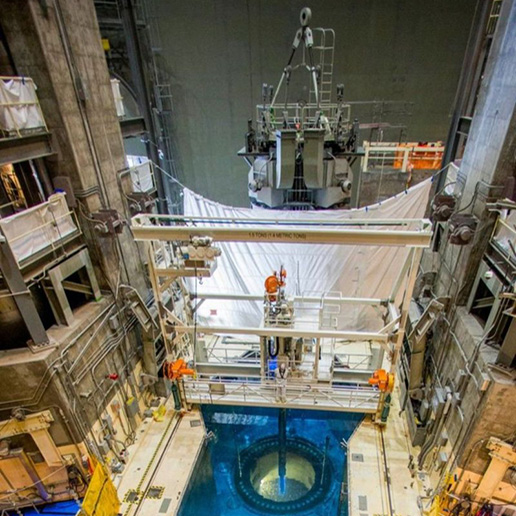

Outage Critical Cranes

Performance of an outage critical crane has the potential to impact refueling outage duration at an operating nuclear plant. As nuclear plants continue to reduce outage duration, outage critical cranes, polar or reactor building crane, cask handling, and turbine building cranes increasingly affect the critical path outage time. Operations rely on dependable, well-built cranes that are designed specifically for the needs of that specific large power plant or small modular reactor. PAR Systems has extensive experience in designing and building new outage critical cranes as well as upgrading crane performance for an existing fleet. Contact us to learn more about our expertise designing and manufacturing outage critical cranes for power plants.

Polar cranes

Polar cranes, or reactor building cranes, serve essential roles in fuel assembly operations, reactor head removal and replacement, and versatile lifting requirements that cater to a range of maintenance and operational tasks with the utmost quality and safety. Operating on a circular runway, polar cranes are designed for heavy lifts and primarily used for reactor head removal and replacement as well as facilitating refueling outages.

PAR has designed and built polar cranes that perform plant maintenance and operational functions from the dawn of the nuclear era. Our designs improve personnel safety, productivity, and reliability of the plant through custom tailored features for the application, safety mechanisms and precision positioning in a single failure proof design.

Cask handling cranes

Nuclear cask handling cranes, also known as spent fuel handling cranes, are specialized lifting devices used in the nuclear industry to handle and transport heavy casks containing spent nuclear fuel or other radioactive materials.

PAR has experience designing and building custom cask handling cranes to ensure the safety and efficient movement of nuclear casks throughout various stages of the nuclear fuel cycle, including storage, transportation, and disposal. We recognize the significance of effectively managing precise operations while prioritizing safety and dependability.

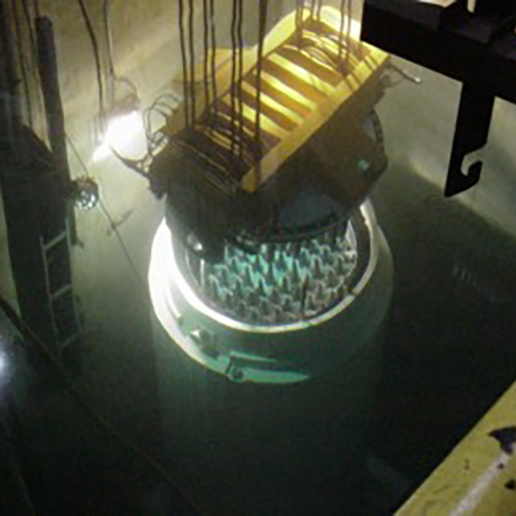

Fuel Handling Equipment

Fuel handling equipment plays a critical role in nuclear power plants and small modular reactors (SMRs) by facilitating the safe and efficient handling of nuclear fuel throughout various stages of the nuclear fuel cycle. PAR Systems designs, manufacturers, tests, and supports refueling and fuel handling systems for the following processes.

Fuel Loading and Unloading

Fuel handling equipment is responsible for the loading and unloading of nuclear fuel into and out of the reactor core. PAR designs systems that transport fuel assemblies from storage to the reactor vessel and the precisely position and insert fuel assemblies into the core during refueling operations.

Our systems ensure safe and efficient handling of nuclear fuel, including precise positioning and insertion of fuel assemblies, transfer to storage pools or dry cask storage systems, repairs or replacements, and separation of reusable materials. Our fuel handling systems have proven to improve operational efficiency, minimize downtime during refueling, and optimize the availability of nuclear power plants and SMRs.

Image courtesy of Southern Nuclear

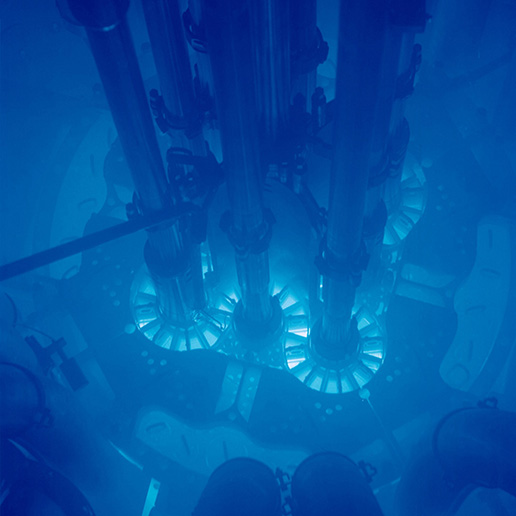

Fuel Storage and Management

PAR fuel handling equipment also assists in the storage and management of spent fuel and fresh fuel assemblies. The involves safe transfer of fuel assemblies to and from storage pools or dry cask storage systems. Our expertly designed equipment helps power plants ensure proper handling and shielding to protect personnel and the environment from radiation exposure.

Operational Efficiency and Reliability

Efficient and reliable fuel handling equipment is crucial for minimizing downtime during refueling operations and optimizing the availability of nuclear power plants and SMRs. Well-designed equipment and automated systems can streamline fuel handling processes, reducing human error and improving overall operational efficiency.

The PAR Advantage

Providing experience, innovation, and dependability for power plants

- In 1961, PAR launched as a business in the nuclear arena.

- We have the deep expertise needed to create products that work in high radiation environments.

- Unique customer problems require new thinking and new solutions like our TensileTruss Technology which was used at Fukushima Daiichi and Chernobyl.

- Customers return to PAR to replace or refurbish our older systems often 20-30 years later.

- Our long history in nuclear technology has helped us earn the trust and loyalty of our customers.

- We support our products for their entire usable life.

- Customers can work directly with our design team.

Our expertise shows in each element we craft.

Certified in all the right places.