Joining and Fastening Systems

Innovative joining systems from PAR add automation to a variety of joining methods to suit the needs an array of joining applications. We are experts at a wide variety of materials and applications, including challenging materials such as silicones. These systems help improve cycle times, increase production quality and volume, and minimize or eliminate human error.

Our Systems

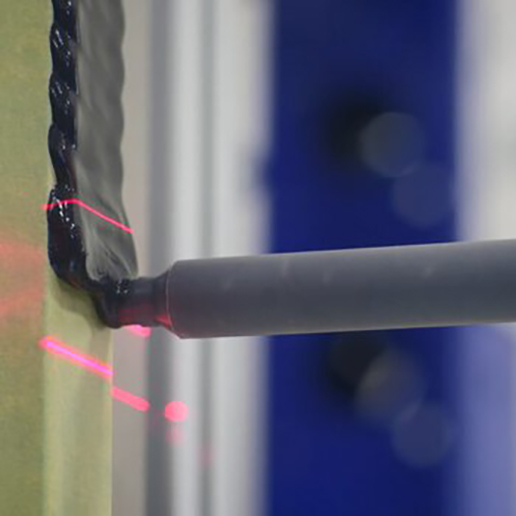

Adhesive Dispensing

Adhesive dispensing systems help ensure a highly precise and consistent adhesive application with automation and adaptability oriented features. These systems provide the precision necessary to meet the most stringent requirements and create monumental efficiencies.

Our automated sealant and adhesive systems can include active seam tracking, integrated process controls, automated calibration and part localization, and more.

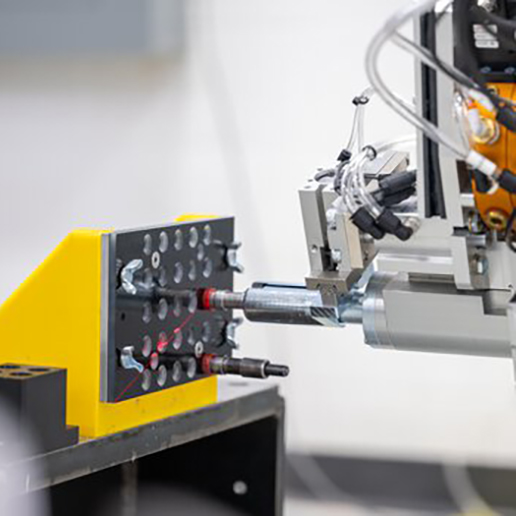

Automated Fastening and Defastening

PAR’s automated fastening and defastening systems use joining methods that allow for accessibility in challenging applications while providing high quality installation.

Automating these processes produces higher quality fastening and defastening processes and improves efficiency.

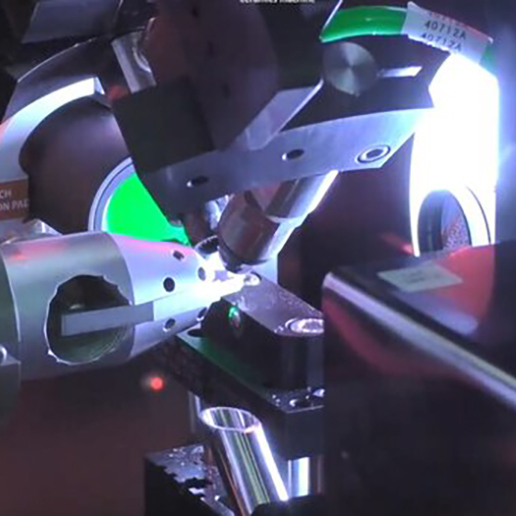

Automated Joining

PAR Systems’ automated joining technologies can weld a wide variety of materials from thick to thin, metallic to non-metallic and complex surfaces. We are experts at substrate materials, both metals and non-metals, and challenging materials such as silicones. We have made systems for joining very small product features to very large material features.

Precision Drilling

Utilizing advanced manufacturing technologies, precision drilling systems from PAR ensure the highest-quality and most efficient precision drilling possible.

These advanced manufacturing techniques include full scanning, advanced software, and measurement workflows that automate the drilling process for improvements to production quality and volume.

Our expertise shows in each element we craft.

The PAR Advantage

Experience. Automation. Partnership.

We design, manufacture, test, install, and support all of our systems for their entire usable life. Our automated joining systems are designed to be highly precise, adaptable, and efficient, ensuring that any joining application can experience the benefits of automated operations. Through our worldwide service organization, we offer dedicated support from a team of local field service engineers, and our global consulting team can resolve the most complex engineering challenges.