Coating Systems

Put cutting-edge coating systems to work in your operation.

Our coating systems are designed for the latest low particulate, low-friction lubricious coatings. They offer multi-coat and multi-solution capabilities often used for medical devices such as catheters and guidewires, and our lubricity testing systems can help ensure the quality of the coating after it has been applied. Our ultrasonic spray coating systems are highly efficient and reduce wasted materials compared to conventional spray machines.

Your premier partner for medical coating solutions.

- We have over 100 coating machines installed globally across North America, South America, Europe and Asia.

- We have a strong partnership with Surmodics, a market leader in medical coating chemistry to provide a complete solution including chemistry and equipment.

- Our machines support R&D, production, as well as quality departments.

- Coating and curing capabilities

- Available integration with material handling

- Space-saving collapsible tube technology requiring minimum clean room space

Coating Platforms and Related Equipment

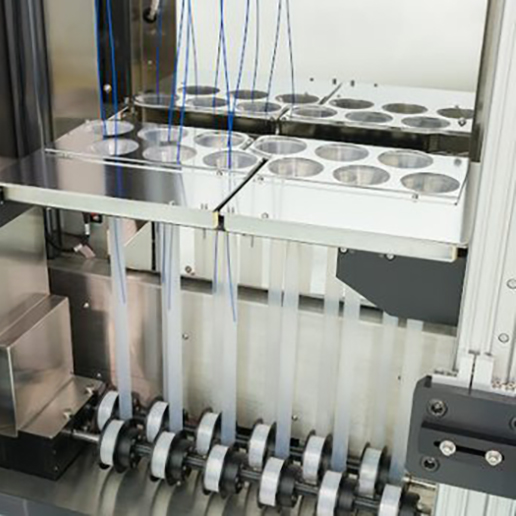

Dip Coaters

Single or dual-batch automated coating platforms.

We are industry leaders in the performance, features, and size offered by our line of dip coaters. We offer two dip coating platforms: automated and semi-automated. This coating equipment is built to maximize efficiency in production and to work effectively in small spaces without bending devices.

Lubricity Testing

Unmatched medical device testing equipment.

Accompanying our line of dip coaters is the DL1000 Durability & Lubricity Test System. The DL1000 provides accurate, reliable measurement of the durability and lubricity of hydrophilic coatings on catheters and guidewires. With flexible tooling and easy-to-use controls, this equipment helps maximize productivity and meets the needs of laboratory and production applications.

Spray Coaters

Precise, Integrated Ultrasonic Spraying Platforms.

We can integrate complete ultrasonic spraying platforms that are designed to easily work with your existing equipment. Our systems provide full control of the ultrasonic nozzle, spray shaping, control enclosure, and choice of liquid delivery systems. Reductions in spray material of up to 75% are seen when changing from conventional air spray to an efficient ultrasonic spraying platform. These platforms can work with a variety of materials, such as activators, coatings, grease, inks, liquid, fluxes, oils, silicones, and solvents.

Our expertise shows in each element we craft.

Certified in all the right places.

The PAR Advantage

PAR has decades of experience in the design, installation, and maintenance of complex solutions for industries that use advanced manufacturing technologies. This extensive experience with these particularly challenging applications makes us the best choice to provide specialty coating equipment for your unique needs.

Through our worldwide service organization, we also offer dedicated support from a team of local field service engineers, and our global consulting team can resolve the most complex engineering challenges.