Anti-Sway Crane Motion Controls

Increase Productivity & Cycle Time by up to 40%

EXPERTOPERATOR™ anti-sway crane control system allows for the movement of payloads in a swing-free manner, permitting crane operators to reduce payload swing by 85-95%. This technology has been proven to:

- Increase safety of personnel and equipment

- Improve cycle time by up to 40%

- Reduce operator training time

- Provide more accurate load placement

- Reduce crane maintenance and extend crane life

To read about anti-sway crane technology in action, read about how it has been used in the automotive manufacturing industry.

How It Works

EXPERTOPERATOR™ is a hardware module that converts pendent commands into expert commands issued to motor drives.

The system intercepts operator commands, then modifies those commands into what a seasoned expert would generate. The modified commands are then issued to the crane. This allows novice operators to drive as proficiently as their experienced counterparts, moving loads safely in a swing-free, efficient manner.

EXPERTOPERATOR adapts to any control system already in use. This makes the integration short and seamless. The typical installation usually takes a day or less, which keeps your downtime to a minimum.

The Benefits of EXPERTOPERATOR™

- No Adjustments Needed: for height, sling length, and load.

- Increased Safety and Collision Prevention: Load sway prevention reduces risk of equipment damage and personal injury.

- Minimized Downtime: This retrofit solution integrates into your existing hardware platform with typical installation time of 1 day.

- Increase Productivity: Hundreds of operator studies demonstrate that cycle time improves by 10% to 40%.

- Maintenance Reduction: EXPERTOPERATOR is the only anti-sway crane technology that does not require sensors of any kind, even with complicated rigging configurations.

- No Height Restrictions: As a sensorless system, the predictive algorithm within the crane controller works at any crane height.

- Compatibility: Seamlessly works with existing VFDs, radio and tethered pendants with continuous or multi-step functionality.

- Increased Accuracy: Accurate load placement is simple because operators focus on positioning rather than swing correction.

- Minimal Training: Novice operators perform as well as their experienced counterparts, reducing the need for extensive training.

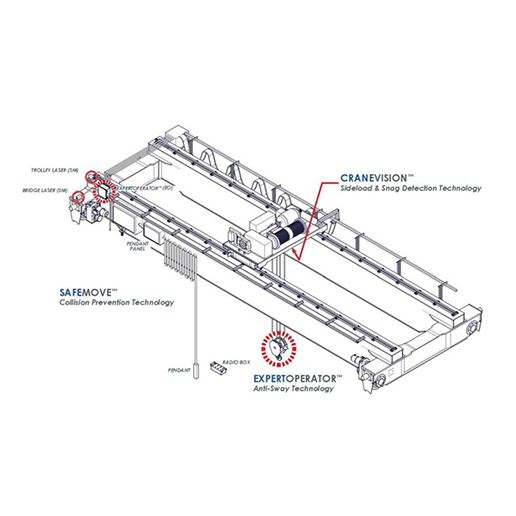

Maximize crane lifting operations with our complete platform of crane motion controls: anti-sway, collision prevention, side load and snag detection, and automatic positioning.

-

EXPERTOPERATOR™

-

SAFEMOVE™

-

CRANEVISION™

-

AUTOMOVE™

SAFEMOVE™ Collision Prevention

SAFEMOVE enhances an operator’s ability to make complex moves safely and avoid collisions between payloads and surrounding equipment. Virtual safety zones can be easily configured throughout the workspace, and quickly enabled and disabled. SAFEMOVE can limit crane motion in multiple regions throughout the workspace and can be used in conjunction with EXPERTOPERATOR technology.

CRANEVISION™ Side Load and Snag Detection

CRANEVISION is a combination of advanced motion controls and machine vision technologies. Vision-based crane manipulation helps the operator avoid side pull and snag conditions for safer crane operations. With CRANEVISION the crane is made safer and smarter. Dangerous conditions, like off-center hoists and snags, can be detected and appropriate action taken to avoid accidents.

AUTOMOVE™ Automatic Positioning

AUTOMOVE allows for automatic and precise payload positioning utilizing standard crane controls. Automatic motion can be initiated and monitored by an operator. AUTOMOVE builds on the foundation of PAR’s proprietary anti-sway crane technology, which permits cranes to move without payload swing.